I’ve promised that I would share the video showing the reflow process in action. I’ve compiled it yesterday and finished it today so here it is, enjoy. I will be making some more test boards to fine tune the process to get it working perfectly. Once done I will post some more videos detailing how to process runs. Please bear in mind that the video is at 12x normal speed so the reaction is a lot more gradual than what it appears in the video.

Testing Phase 1 – With limited time

Ok so the cover photo of this post is a bit strange given that the blog is about electronics and I’m from South Africa. The reason for it is that I’m going to move to Canada within the next few months. I’ve applied for a position at our Canadian branch and have gotten the job :). So this leaves me with less time for the project. Luckily we’re almost there. Over the past few weeks I’ve been busy redesigning the circuit boards, again, so that I can get it ready for production. As mentioned in my previous post, I’ve started collaborating with one of the blog’s readers, Mark. We’ve just had someone else go over my circuit designs and some errors were spotted which lead to the redesigning of the circuit. This has only been done for the Arduino shield version of the board and not for the stand alone version of the board. I’m going to focus on getting the Arduino shield version ready for production should anyone be interested in it.

Posted in Uncategorized

Getting closer to the finish line

Hello Everyone

Time just goes by way to fast, or maybe I just don’t have enough 😉 The past month I’ve been busy with redesigning the PCB to fit into an enclosure. I then designed one to fit the bill. One of the blog’s readers have come in contact with me and has given me loads of insightful tips and guides, Thanks Mark, it’s much appreciated. As such I have again redesigned the PCB to be a single board design instead of multiple boards. This will help to reduce costing. I’ve also come up with an alternative to the shield design. I’ve basically taken a Mega 2560 R3 and redesigned it around my application. The reason for this is that the progam space is the limit of that of the Arduino UNO. With the ATMega2560 it is not even a quarter of the space. So there are much room for additional menus and improvements.

Posted in Uncategorized

Finalized Firmware – YEAH (“,)

Hello Everyone

It’s been a month again, wow. In any case, in the past month I was able to complete my firmware and it seems to be working correctly. Below is a video demoing the firmware for you on Youtube. I’ve hooked up the reflow oven shield to the toaster oven and everything seems to be running smoothly. I have also managed to make the shield compatible with the Arduino Mega, so now it is compatible with the Arduino UNO as well as the Arduino Mega. Since the overall compiled sketch size is 31.84 kB, it allows for further expansion of the program if your using a Mega. I am now in the process of redesigning the circuit boards to as to be able to build it into an enclosure. Click on the “Read more” to view a video demo of the firmware.

Temperature Calibration Resolved

Hello Everyone

Its been a while again since my last post, but I’ve been a bit busy and preoccupied with various other things as well. Luckily I have some good news at least regarding the temperature measurement of the unit. I was working on the temperature calibration algorithm but got stuck. I seemed to have hit a mental block on how to proceed. I then re-evaluated whether the my initial calibration was working correct or not. I established that it wasn’t working correctly on initial testing. According to the datasheet of the AD597, the AD597 can only source an output up to 2V below the supplied voltage (Vcc). Vcc in my case is 5V so then according to the datasheet, my maximum output should only be 3V that I should be able to get from the AD597.

Solder Reflow Oven Shield Hardware Solved!

So when I finished with my hardware post previously I didn’t get the unit to work properly. The relays were working correctly but the temperature measurement wasn’t working correctly. I got weird values from the thermocouple conditioner and whether I heated up the temperature probe or cooled it down, it didn’t make a difference in the RAW measured value that I was getting in. So I thought that maybe I blew my thermocouple conditioner. That is when I removed it from the board and accidentally broke one of the legs, causing me to have to order another two for testing.

Automatic Battery Maintainer – Done and Dusted

Hello Everyone

I hope that you all are still doing great. I finally had the time to fault find my battery charger/maintainer circuit. Through fault finding the circuit I came to better understand it since I took the design from another website. So the first part of the circuit is the LM317 power supply section which consist out of two LM317 chips, the first is used to limit the current while the second is used to adjust the output voltage. The dip switches is to adjust the current limiting value. I chose dip switches since a 3W portentiometer would have been too expensive in comparison to the DIP switch alternative and the amount of times that you will be adjusting it will be minimal.

Posted in Uncategorized

AD597 Thermocouple Conditioners Arrived (“,)

Hello Everyone

So at long last I have received my replacement AD597 thermocouple conditioner ICs and I set out to create the breakout board to fault find what went wrong previously.

Posted in Uncategorized

Automatic Battery Maintainer

Hello Everyone

As promised, I was working on an automatic battery charger alongside my solder reflow oven shield. The idea came from needing a battery backup for our Wendy house alarm system so that if the power fails that the alarm is not wrongly activated (Different partition connected to the house alarm system, i.e. different zones). I found most of the information that I needed over here but didn’t have all the right knowledge so I had to consult online a bit to get all the theory correct. So I’ve designed the circuit board during the months of November and December and finally built it on the 3rd of Jan 2014. This is what I came up with thus far:

Posted in Uncategorized

Solder Reflow Oven Shield Reloaded

Hello Everyone

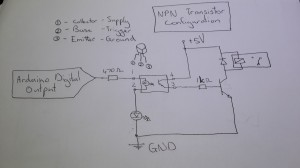

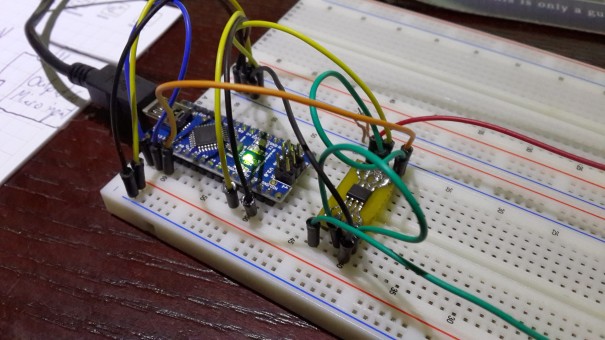

It’s been a while again, happy new year to everyone and I hope that you all enjoyed a wonderful festive season. I revised my circuit again and tested the relay functions before creating the board again. Reason being that I accidentally bought PNP transistors rather then NPN transisistors. Here are the circuit diagrams for relay configurations using either a PNP transistor:

or a NPN transistor.

Posted in Uncategorized